What are the differences between standard, airtight installation and installation in the insulation layer?

| Standard mounting | Sealed installation | Installation in the insulation layer | |

|---|---|---|---|

| Durability | 3-5 years of leakage maintenance | 15-20 years impermeability | more than 20 years of leak tightness |

| UW permeability | 1.1 UW | 0.9 UW | 0.7 UW |

| Energy efficiency | Standard efficiency, possible thermal bridging | Minimization of thermal bridges, better insulation | Compliance with standards and guidelines, highest energy efficiency |

| Reduce heating costs | Standard costs, no change for window replacement | Reduce annual insulation costs by up to 15% (relative to conventional installation) | Reduction in annual insulation costs up to 25% (Compared to ordinary installation) |

| Sound insulation | Standard insulation | Improved sound insulation | Optimal sound insulation according to standards |

| Installation costs | Lower costs | Higher costs associated with better materials | Investment in upfront costs for long-term savings |

| Application | Recommended for buildings where the main priority is not energy efficiency, but cost of installation | Recommended for places where thermal and acoustic insulation parameters are important | Recommended for modern buildings that require the highest standards of energy efficiency, safety and sound insulation. |

| Products used for installation | Installation foam, anchor | Installation foam, vapor-proof tape, vapor-permeable tape | Expansion tape, under-window profile, liquid window film, quick-setting adhesive, primer, installation board, insulation wedge (type II) |

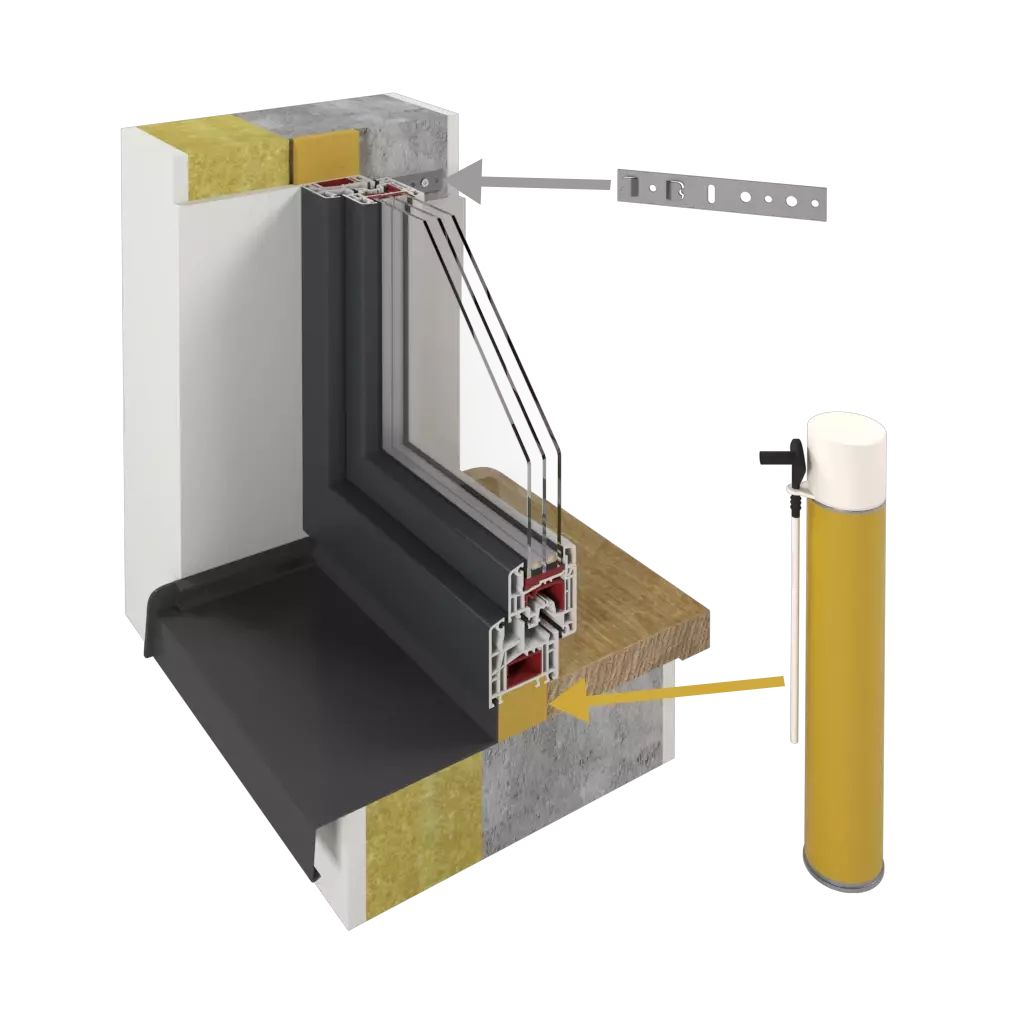

Standard installation involves using mounting foam and anchors to fix the window. The durability of maintaining the seal is usually 3 to 5 years. This is the recommended installation when the main priority is not energy efficiency, but installation costs. The heat transfer coefficient (UW) for this type of installation is usually around 1.1 UW.

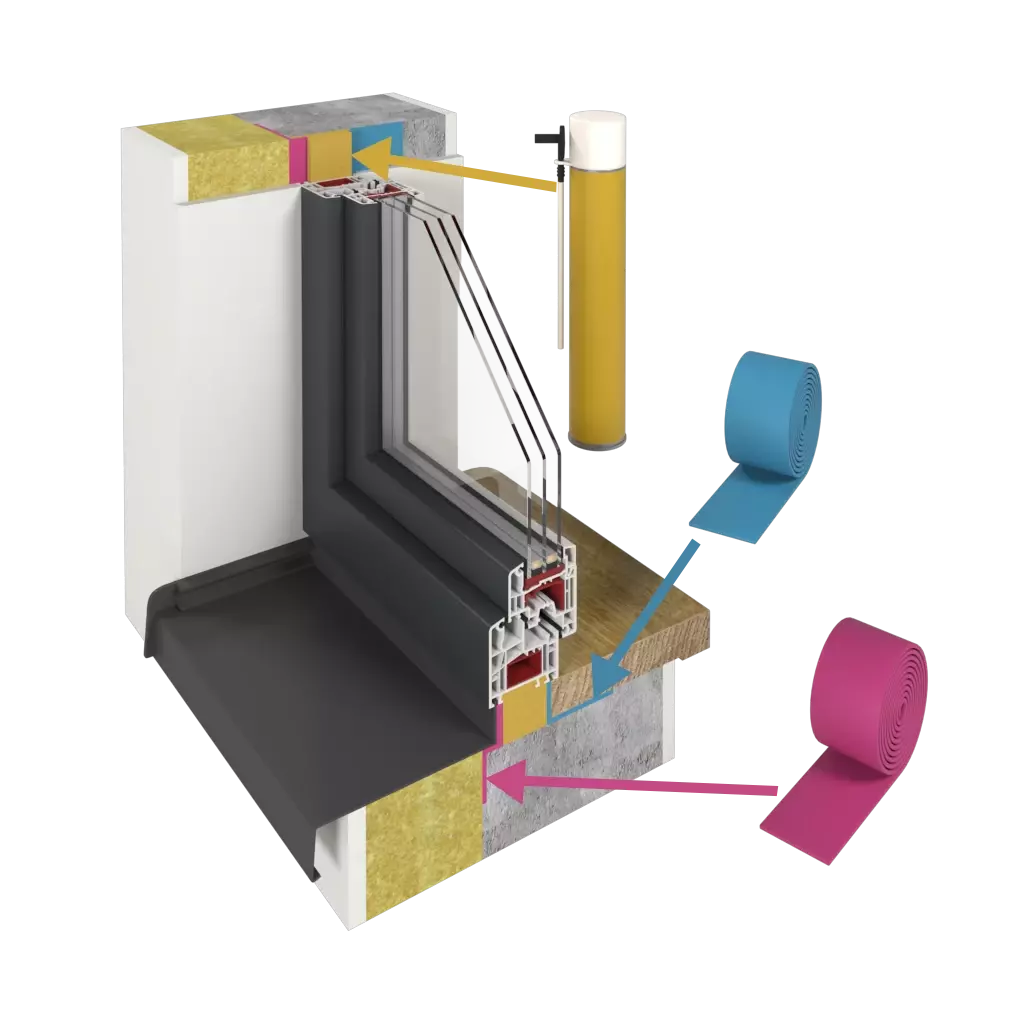

Tight installation is a more advanced method, using mounting foam, vapor-proof tape and vapor-permeable tape. It aims to minimize thermal bridges and improve sound insulation. The durability of maintaining airtightness is 15 to 20 years. It is recommended in areas where thermal and acoustic insulation parameters are important. The heat transfer coefficient (UW) for sealed installation is about 0.9 UW.

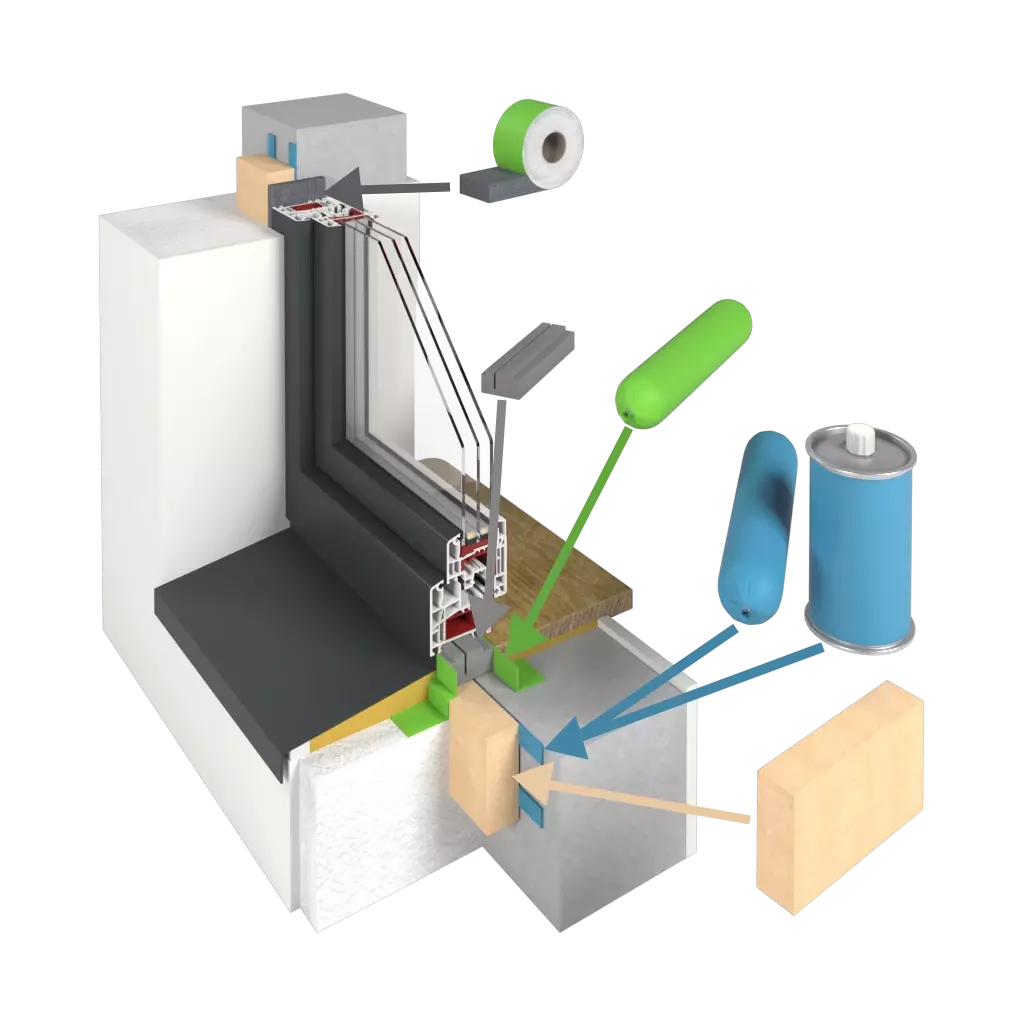

Installation in the insulation layer (MOWO) is the most advanced technique, which uses a series of specialized materials such as expansion tape, under-window profile, liquid window film, etc. It aims to achieve the highest energy efficiency and provide optimal sound insulation. Durability of leakage maintenance exceeds 20 years. It is recommended for modern buildings that require the highest standards of energy efficiency, safety and sound insulation. The heat transfer coefficient (UW) for installation in the insulation layer is about 0.7 UW.